- Gat No. 22, Village Bhandgaon, Pune – Solapur Highway, Dist. Pune.

Call Anytime

About G.D.Metsteel

Quality Research Orgnization

Quality Research Orgnization

Quality Research Organization

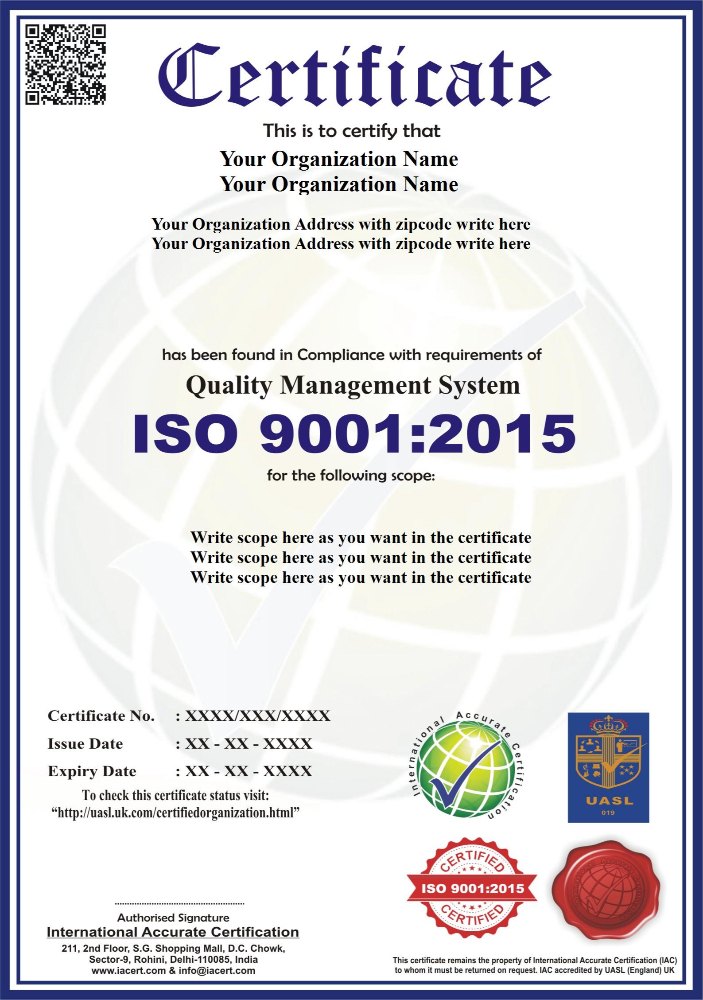

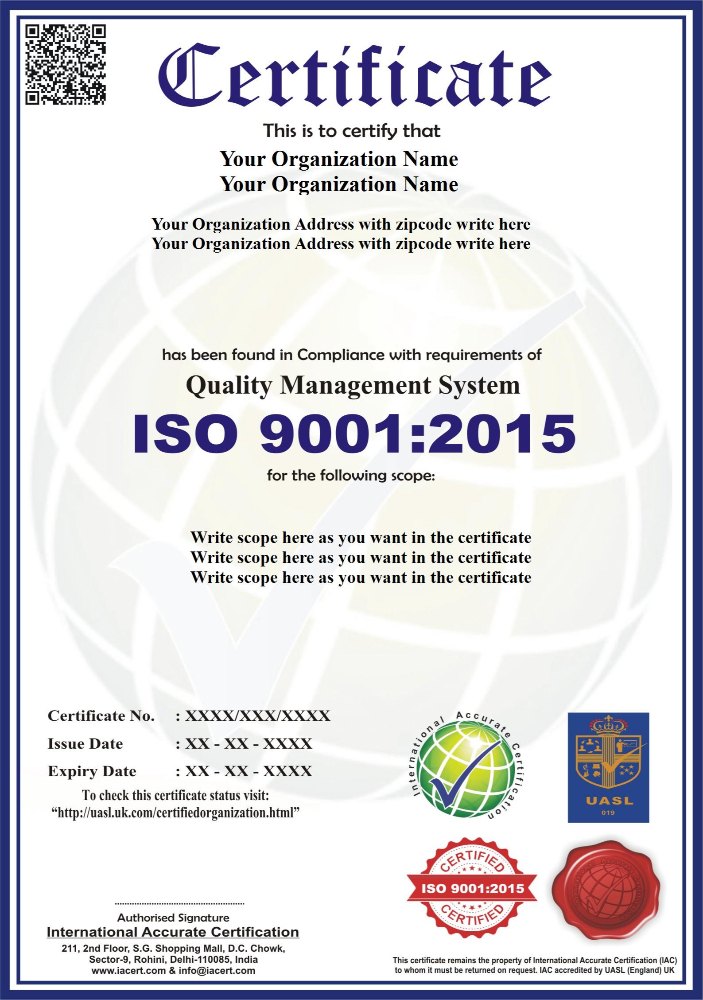

International Organization for Standardization

International Organization for Standardization

International Organization for Standardization

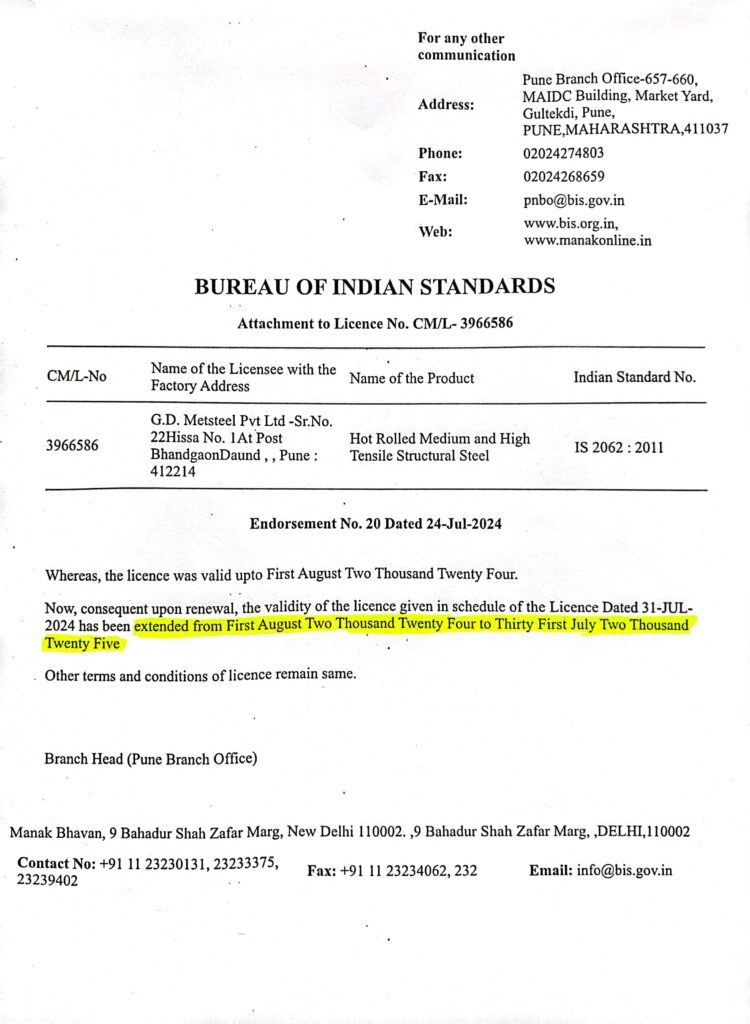

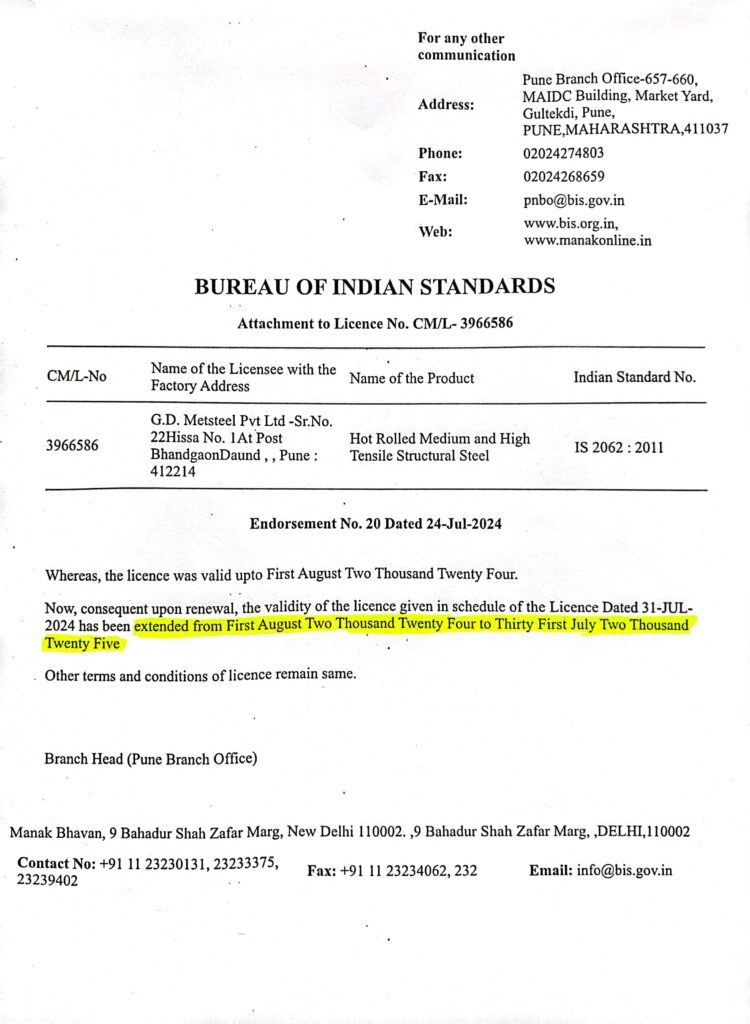

Bureau Of Indian Standard

Bureau Of Indian Standard

Bureau Of Indian Standard

Indian Standard Institution

Indian Standard Institution

Indian Standards Institution

IS:2062

- Legacy of Quality

- Extensive Product Range

- Advanced Infrastructure

- High Production Capacity

- Robust Logistics

0+

Years Of Legacy

About GD Metsteel Pvt Ltd

Leading Structural Steel Manufacturer Since 1984

G. D. Metsteel Pvt. Ltd. has a legacy since 1984 and originated its first fully automatic continuous structural

steel rolling mill in Yavat, Pune under the brand name “G D MALHOTRA”.

The company manufacturer an extensive range of structural steel products of MS which mainly includes Angles, Channels, Flats, Beams, Bars & Serrated Flats sections. The single mill grown to three and the company’s infrastructural strengths today include an induction furnace and a fully integrated testing lab. 16” & 10” automatic mill with 25 mtr reheating furnace, coal plant and 6 stands, a cooling bed of 160’ x 12 ‘ and two shearing machines to cut 2” plates.

Our organisation has distinguished itself as a quality conscious entity from its very inception, constant

modernisation and upgradation has seen. The G D METSTEEL grow into a preferred brand with an array

of clientele comprising both private and public sector companies like construction industry especially for

building, land development projects, infrastructural projects, government projects, transmission towers,

automotive components and systems etc. We would like to inform you that we are approved by many

organisation like ISI, BIS, QRO etc.

Quality Assurance

Lab Testing

Lab

The brand equity we have earned in the market is the

direct result of our focus on quality. Excellence has

always been our watchword, from the establishment

of the first fully automatic steel rolling mill, in 1984,

to our policy of continuous improvement in process

and product. Our Research and Development team is

constantly innovating engineering solutions within

our manufacturing facilities that have consistently

yielded faster, better, and safer production

processes. Our modern manufacturing facility at

Yavat houses a state of the art laboratory with the

latest testing equipment, such as a spectrometer and

a UTS machine.

STRENGTH TESTING

Tensile

Our strategy of backward integration, which

includes the acquisition of a billet manufacturing

unit, is another aspect that allows us greater

control over the manufacturing process, every

batch of billets is tested for composition, quality

and random tests are also conducted throughout

the production process. A dedicated Quality

Control team ensures compliance with IS 2062

Grade A production. Our holographic MILL TEST

Certificate assures buyers of the quality of the

product. To further build customer confidence our

QA policy welcomes third party inspections of our

plant as well as materials.

We are being certified with following approvals :

Quality Research Orgnization

Quality Research Orgnization

Quality Research Organization

Indian Standard Institution

Indian Standard Institution

Indian Standard Institution

Bureau Of Indian Standard

Bureau Of Indian Standard

Bureau Of Indian Standard

International Organization for Standardization

International Organization for Standardization

International Organization for Standardization

RELATIONS BONDED WITH:

Quality, Affordable, Manufacturing and Industrial services

G. D. Metsteel Pvt. Ltd. has a legacy since 1984 and originated its first fully automatic continuous structural

steel rolling mill in Yavat, Pune under the brand name “G D MALHOTRA”.